The latest potential breakthrough to address climate change is promised by producing hydrogen from water—so-called green hydrogen, because this method of production does not emit greenhouse gases. There is a problem, however. The chemical process to make “green” hydrogen depends on minerals in rare supply or from sources in China and/or are produced by Chinese companies.

A solution to this problem could be available in the form of improving economic ties with Brazil, India, and South Africa, three of the BRICS countries (the other two being China and Russia) with potential reserves of rare minerals. They are also countries with which the US already has healthy economic relationships. To take advantage of this potential, the Biden administration needs to figure out a way to establish trade agreements with these countries, perhaps granting them the trade preferences they want, even if that runs counter to part of the administration’s protectionist impulses. The EU should also look closely at these opportunities.

Many green technologies and industries championed by the Biden administration and by the EU for batteries, solar and wind power, and electric vehicles are heavily reliant on lithium, manganese, graphite, and other rare earth elements dominated by China. Much less known is the fact that a clean hydrogen-based economy is also dependent on other minerals found in large quantities not only in China but also in Brazil, South Africa, India, and Russia. The Russia-Ukraine conflict rules out Russian access, at least for now, and reducing dependence on China is a goal in Europe and the US. There are no clear obstacles to establishing negotiations with Brazil, South Africa, and India, however. Closer ties between North Atlantic nations and the Global South could potentially benefit all countries, speeding up the transition to clean hydrogen as an energy source.

Hydrogen supplies fuel for some industries and vehicles. But most of this hydrogen is produced in ways that emit carbon dioxide. Clean hydrogen is produced with lower carbon emissions. Hydrogen production pathways are typically characterized by colors:

- Gray hydrogen utilizes natural gas—this is the most widely used pathway for producing hydrogen today and has carbon dioxide as a by-product.

- Black hydrogen uses coal, generating a lot of carbon dioxide as a by-product.

- Blue hydrogen uses natural gas but is complemented by the capture of the carbon dioxide by-product.

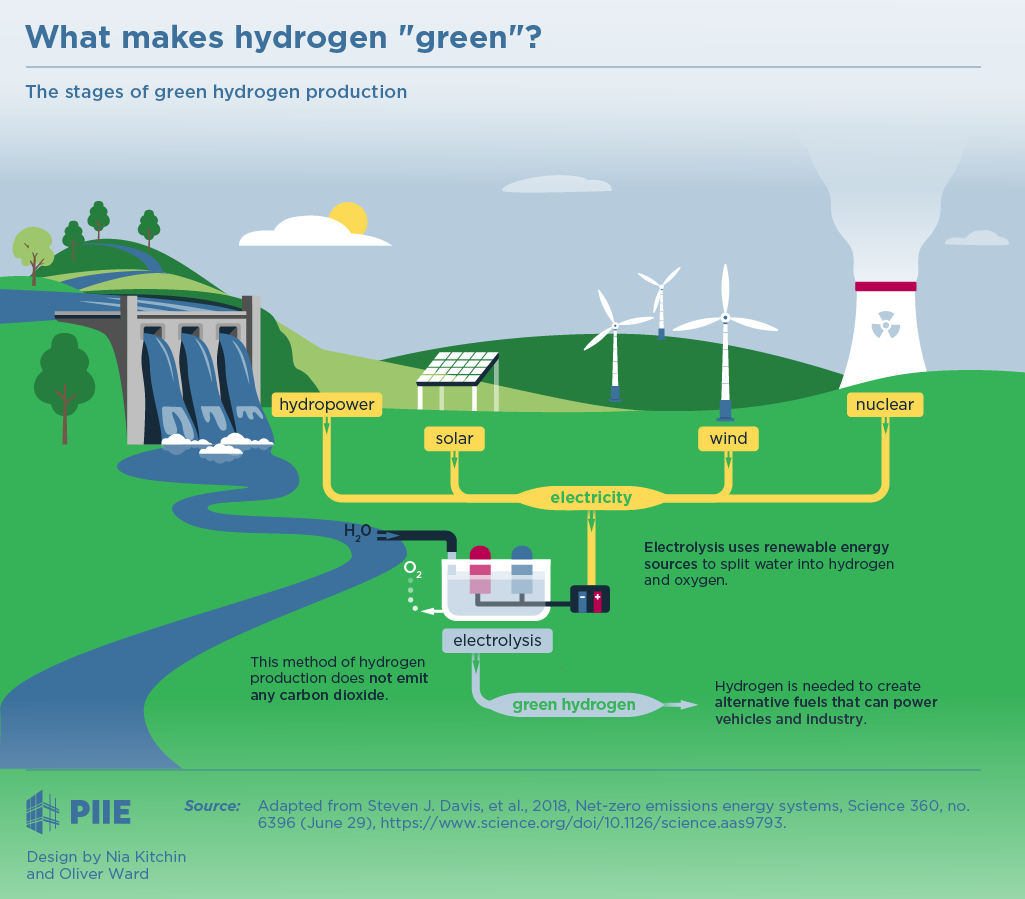

- Green hydrogen is produced by splitting water molecules using a process called electrolysis. Electrolysis relies on an electrical current derived from renewable energy sources. Importantly, this pathway does not result in any carbon dioxide by-products (see graphic).

Much of the world, and notably the US and the EU, has turned its attention to the production of green hydrogen. While there are several difficulties in the production of green hydrogen, one of the main bottlenecks is the electrolysis of water.

Water electrolysis involves breaking up a water molecule into its hydrogen and oxygen components. The process utilizes an electrical current in appropriate media coupled with catalyzers to produce a chemical reaction. The more technologically advanced, most efficient, and expensive method to electrolyze water involves the use of highly acidic media and metal catalyzers that are not easily corroded in acidic environments. These metals belong to the platinum group metals (PGMs), composed of platinum, iridium, rhodium, and three other elements. PGMs are mainly found in South Africa, which holds more than 80 percent of the world’s reserves of iridium and rhodium.

Another method for water electrolysis uses alkaline, noncorrosive media. This method is not as efficient as the one described above, but it does not need precious metals as catalyzers. Instead of PGMs, iron group metals such as iron, nickel, and cobalt are used. Nearly half of the world’s reserves of iron group metals are found in Brazil, Russia, China, and India. Brazil and India alone have some 40 percent of global reserves of these metals.

The development of a green hydrogen industry has long been an objective of many countries, as well as energy companies. This goal has been elusive because of its expensive production process that relied on the creation of supply chains to source the critical metals listed in the table below. Recent initiatives by the US, EU, Japan, and China have made low-carbon technologies increasingly cost competitive, reducing the onus of green hydrogen production. New hydrogen production tax credits in the US Inflation Reduction Act (IRA) of 2022 are a major factor in making it more cost competitive. Europe’s subsidies and its Emissions Trading System (ETS), which has effectively raised the price of fossil fuels, also increase hydrogen’s likely use.

| Critical metals for the production of green hydrogen from the electrolysis of water | |

| Acidic media | Alkaline media |

| Iridium | Iron |

| Platinum | Nickel |

| Rhodium | Cobalt |

| Source: US Department of Energy. | |

But reducing costs is not enough. The US and Europe must also secure the critical metals upon which the industry inevitably relies. In a world marked by war and increased animosity towards China, advanced economies will need to foster greater proximity with Brazil, South Africa, and India. Mutual economic arrangements—via trade agreements or other cooperative means—must be pursued, to the benefit of not only these supplying countries but also the US and Europe.

Data Disclosure

This publication does not include a replication package.